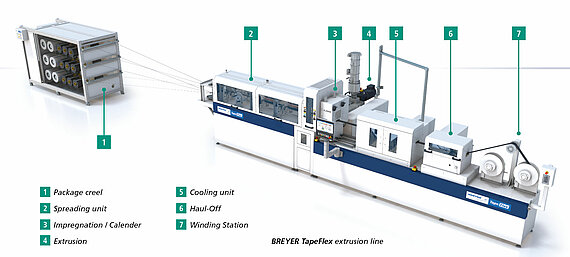

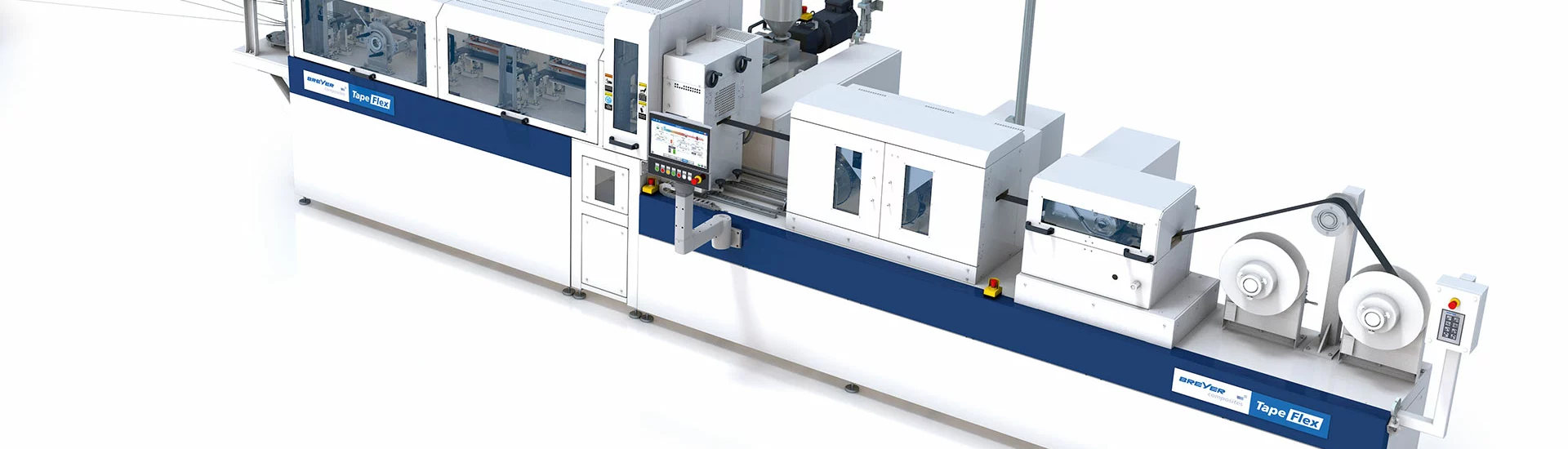

BREYER TapeFlex

Extrusion line for unidirectionally fiber-reinforced thermoplastic tapes

BREYER offers you the complete extrusion line for economical tape production:

- Package creel

- Spreading unit

- Impregnating tool

- Extruder

- Calender

- Cooling section

- Winder

We optionally offer fiber distribution and spreading, tape accumulator and optical analytic systems.

Technical Data

Width of the tape: 75 mm and 240 mm(other widths on request)

Thickness of the tape: 100 µm – 350 µm

Matrix Material: PA, PP, ASA (other materials on request)

Fiber Material: Carbon, Glass, Aramid & Natural Fibers

Line Speed: 12 m/min

Impregnation

The impregnation tool is the essential part of the whole tape production line. This sets the course for the quality of the tape. In the impregnation tool, the thermoplastic melt is flexed into the spread fiber web by deflections, completely enclosing each individual filament with the melt. This creates complete impregnation and wipes off excess melt before the impregnated tape exits the impregnation tool. In addition to the impregnation itself, special attention was paid to user-friendliness. This makes it as easy as possible to insert the fibers and opening and closing is done in no time at all thanks to the appropriate design.

Calendering

Calendering serves to fix the surface of the tape directly after impregnation. In this way, it can be guaranteed that the tape emerging from the impregnation tool is smoothed directly and that the high-quality impregnation can be maintained with the fibers being fully spread.

Your manufacturing benefits

Reliable extrusion from the extruder specialist.

A wide range of extruders and screws is available for the thermoplastic matrices to be processed.

Variety of fiber types: carbon and glass fibers are particularly suitable (due to the tensile forces).

Simple and intuitive operation: with graphically displayed system components on the touch screen.

Flexibility in tape dimensions: When configuring the system, we focus on your wishes.

- Compact system design for optimal accessibility.

- Safe and product-friendly production through pressure-reducing tool design.

- Easy product change and easy cleaning of the extruder and connection.

- Easy handling (opening and closing) of the impregnation tool.

- Good accessibility. Controlled approach possible when the tool is open.

- Closing the tool while the line is running.

- Generation of superficial low-fiber thermoplastic matrix adhesive layers

Further information you receive from our team BREYER Composite:

Contact partner Sales

Franziska Stadtmüller

T +49 (0) 7731 920438

franziska.stadtmueller@breyer-extr.com

Contact partner Technology

Michael Pick

michael.pick@breyer-extr.com

T +49 (0) 7731 920155